Our building work continues at the Museum. After the repair to the two chimney stacks using reclaimed brick work has continued on cleaning and clearing the roof valleys of debris. That went relatively quickly and the site has moved onto the external repairs.

What are we repairing?

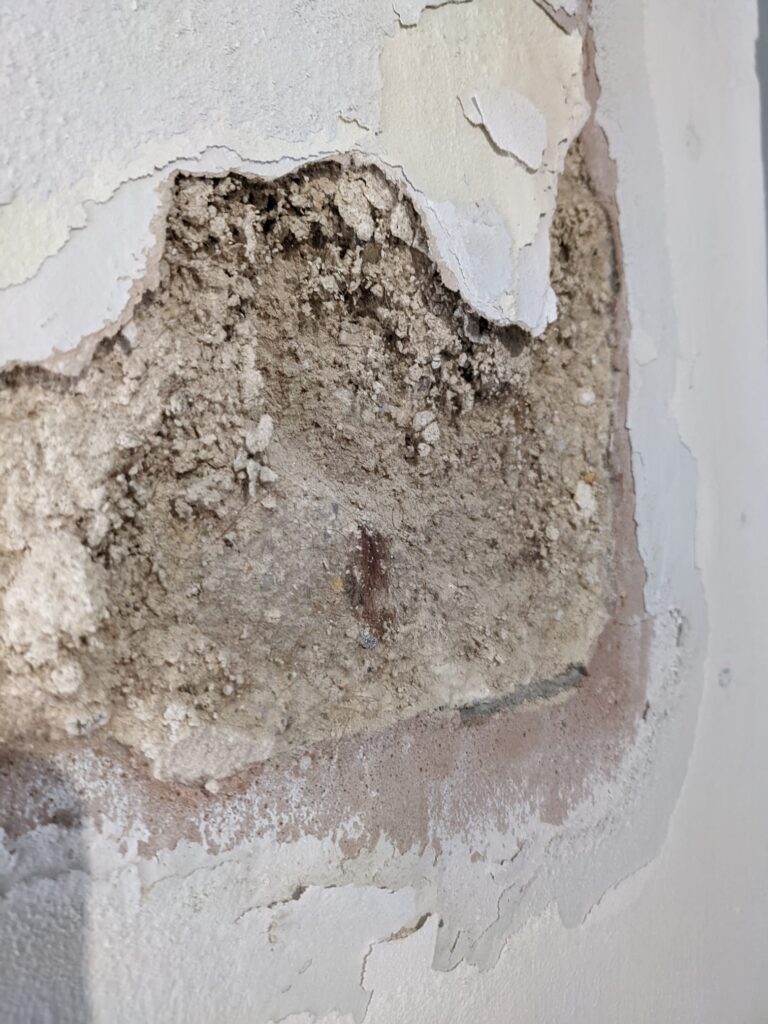

These repairs are all part of standard maintenance of a historic building. Repairs have been looking at places where the render has gotten old and cracked over time. It has also discovered places where incorrect concrete render has been used to as a repair in the past. Cracking can lead to all sorts of issues like water getting behind the walls and larger cracks appearing when the weather freezes in the winter, this all leads to paint flaking off as well.

What is Render and why is it important?

Render is the smooth layer of plaster that makes up final layer of the exterior of the building, it’s what gets painted.

The White Horse Inn, the building the Museum of Cambridge is in, is a 16th century timber framed building. Timber buildings were very popular and easy to build because of the prevalence of oak as a building material. They are less popular now because they were very susceptible to fire and many old buildings were cleared from city centre as new construction and roads were built. We believe that we may be one of the oldest timber framed public buildings in Cambridge.

Timber framed buildings are made of large oak beams. Between the beams which make up the structure to the walls, floor and roof, is lath and plaster. The lath goes horizontally across the timber and the plaster is used to fill in the spaces between the lathes.

At the Museum we have two layers of lath and plaster on our building. The internal walls and then the same process was repeated on the external walls, adding insulation space, but also creating a smooth surface on the outside, keeping water away. The render, or final layer of plaster on the outside needs to be smooth, and perfectly cured to keep the elements at bay.

What is render made of?

Lime render, the traditional building material is made of sand, lime which is a natural material and water. Very old mixtures of plaster included horse hair and other materials to strengthen and improve its curing time. We also have examples of a much older technique, but similar technique, waddle and daub

The construction is similar, wooden pieces (the waddle) are woven or fixed between beams and then packed with a mixture of straw, clay, dung and other available material (daub). It’s finally plastered over to give a smooth finish. The render being repair at the museum is more modern, but in places does still have other additives like horse-hair!

Lime plaster is flexible and most importantly breathable. Letting a historic building breathe keeps the humidity down and the wooden beams very happy.

What’s next?

Work has started taking off the old mix of plaster and concrete which was added in the 1960s and inspecting the beams underneath. Unsurprisingly after many many years since its last inspection, some repairs need to be done to replace beams which haven’t weathered as well. Like many other timber frame buildings there are areas which need to be replaced and repaired after nearly 400 years of wear and tear. Concrete which was thought to be a robust building material isn’t right for timber buildings, though often found on historic repairs.

The works are currently along the Northampton street side on the second floor which we will reopen in the new year once the works are all finished! Stay tuned for more details about repair to our 16th century building.

If you have stories you would like to share on CapturingCambridge.org Cambridge please contact us using the email link on the site.